- Schnell Group: Pioneering Innovation in Reinforcement Processing Equipment for Over 30 Years

- Shaping Tomorrow’s Interiors: Gulf Construct Magazine Features FlyBird Hardware’s Visionary CEO, MR. Naveen Singh Parihar

- Innovative Fire and Smoke Curtain Systems: Enhancing Safety Across 30+ Countries

- ACTS: A Global Leader in Engineering, Testing, and Certification Services

Introduction to Laser Screed Concrete Flooring

In the dynamic and competitive construction industry of Saudi Arabia, precision and efficiency are critical to the success of any concrete flooring project. Laser Screed Concrete Flooring, provided by Indus Arabia, is a revolutionary service designed to meet these demands with unparalleled accuracy and speed. Whether you’re developing an industrial warehouse, a commercial facility, or a large residential project, our laser screed technology ensures that every square meter of concrete is perfectly leveled, durable, and ready to withstand the test of time.

What is Laser Screed Concrete Flooring?

Definition and Process

Laser Screed Concrete Flooring is a cutting-edge technique that utilizes advanced laser-guided machinery to level concrete surfaces with exceptional precision. The process involves using a laser screed machine, which is guided by laser transmitters and receivers to ensure that the concrete is evenly distributed, compacted, and leveled in a single pass. This method produces a perfectly flat, smooth surface with minimal need for additional finishing work.

Advantages Over Traditional Methods

Laser Screed Concrete Flooring offers several advantages over traditional concrete flooring methods:

- Higher Precision and Accuracy: The laser-guided system ensures that each section of the floor is perfectly level, eliminating the inconsistencies often seen with manual methods.

- Faster Project Completion: By reducing the time needed for concrete placement and leveling, laser screeding allows larger areas to be completed more quickly.

- Reduced Labor Costs: With fewer workers required on-site and less manual intervention, labor costs are significantly lower.

- Consistent Quality: The uniformity and consistency of the concrete surface are maintained throughout the project, resulting in floors that are not only flat but also highly durable.

- Fewer Construction Joints: The ability to pour larger sections of concrete reduces the number of construction joints, enhancing the structural integrity and longevity of the floor.

The Role of Innovative Machinery in Concrete Flooring

Technological Advancements in Concrete Flooring

The construction industry has seen significant technological advancements in recent years, particularly in the realm of concrete flooring. Tools like ride-on trowels, early entry saws, and, most notably, laser screed machines, have transformed the way concrete floors are constructed. Among these, laser screed technology has emerged as the most impactful, enabling contractors to achieve the high-performance floors that today’s demanding projects require.

Impact of Laser Screed Technology

Laser screed technology has redefined the standards of concrete flooring by allowing for larger bay sizes, reduced construction time, and improved flatness. Unlike traditional methods that rely on manual leveling and guide rails, laser screeding automates the process, ensuring that the floor is perfectly level with each pass. This automation not only speeds up the construction process but also minimizes the potential for human error, resulting in a superior finished product.

Why Choose Indus Arabia for Laser Screed Concrete Flooring?

Expertise and Experience

Indus Arabia is a leader in the concrete flooring industry in Saudi Arabia, with years of experience delivering high-quality results for a wide range of projects. Our team of professionals is well-versed in the latest concrete flooring technologies, ensuring that each project is completed to the highest standards.

Advanced Equipment

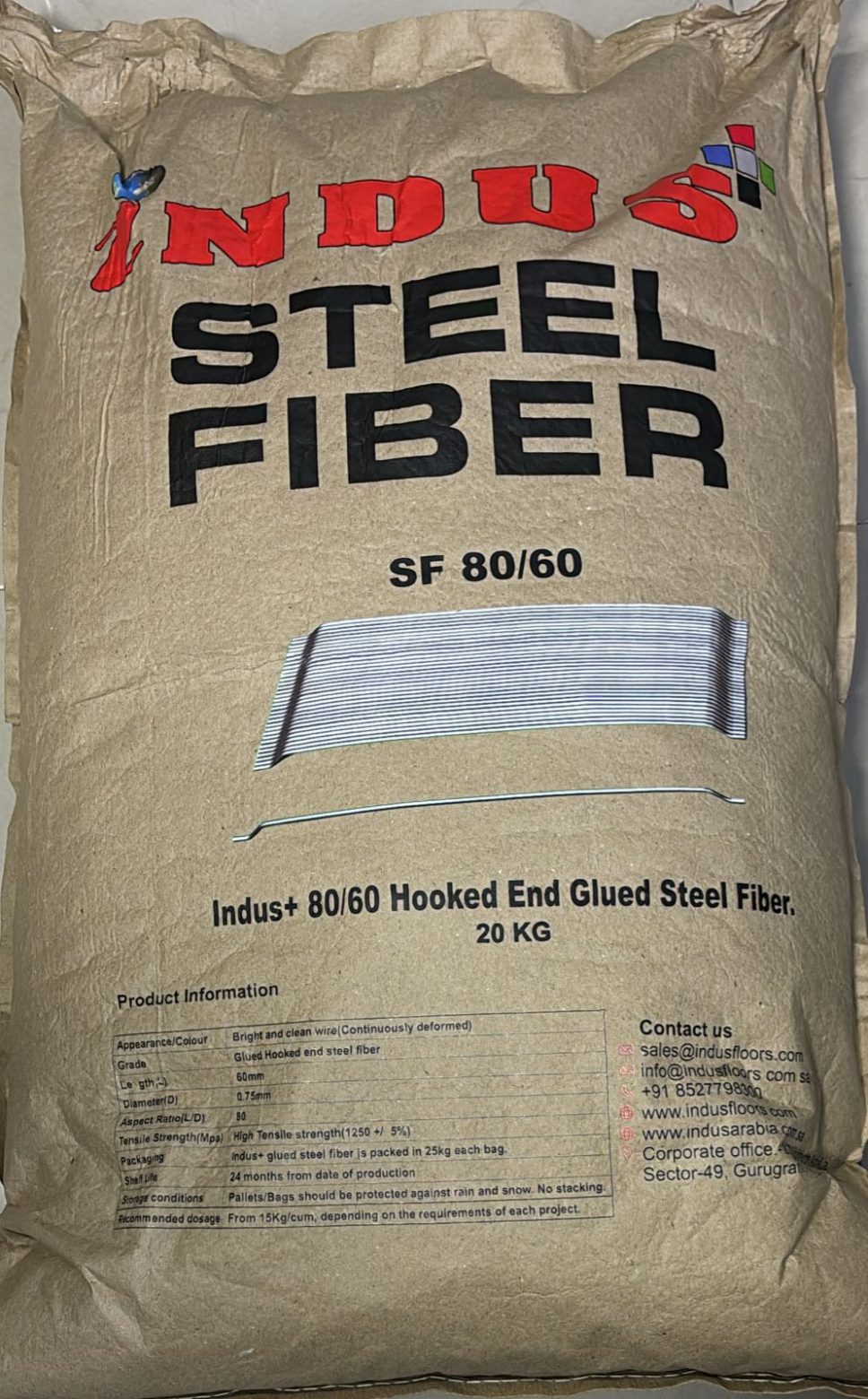

At Indus Arabia, we utilize the latest Somero Copperhead XD 3.0 laser screed machinery, which is capable of laying high-tolerance concrete floor slabs up to 1200m² in a single day. This state-of-the-art equipment allows us to achieve precise flatness levels, including FM1, FM2 (special), FM2, and FM3, in accordance with the TR34 standards. For defined movement slabs, such as those required for high bay racking, we meet stringent tolerances like DM1, Category 1, and Category 2, ensuring that every project meets or exceeds client expectations.

Customization and Flexibility

Every project is unique, and at Indus Arabia, we tailor our laser screed concrete flooring solutions to meet the specific needs of our clients. Whether you’re working on an industrial warehouse, a commercial development, or a large-scale residential project, we offer customized solutions that ensure your flooring meets all necessary specifications and performance standards.

Applications of Laser Screed Concrete Flooring

Industrial and Commercial Projects

Laser Screed Concrete Flooring is ideal for large-scale industrial and commercial projects where precision, durability, and efficiency are paramount. Key applications include:

- Warehouses and Distribution Centers: Ensuring smooth, flat surfaces capable of supporting heavy traffic and storage.

- Factories: Providing robust flooring that can withstand continuous use and heavy machinery.

- Commercial Centers: Delivering aesthetically pleasing and functional flooring solutions for high-traffic areas.

Large-Scale Residential Projects

For large residential developments such as multi-story buildings and housing complexes, Laser Screed Concrete Flooring offers significant benefits, including faster construction times, reduced labor requirements, and superior floor quality. The technology ensures that floors are level, durable, and visually appealing, enhancing the overall value of the property.

Infrastructure Projects

Infrastructure projects, including airports, parking lots, and public spaces, also benefit from Laser Screed Concrete Flooring. The technology allows for the efficient construction of large, flat surfaces essential for these types of projects, ensuring long-lasting performance and minimal maintenance.

The Process: How Laser Screed Concrete Flooring is Implemented

Step-by-Step Process

The implementation of Laser Screed Concrete Flooring involves several critical steps:

- Site Preparation: Ensuring the site is properly prepared for concrete pouring.

- Concrete Pouring and Screeding: Using the laser screed machinery to place and level the concrete.

- Quality Control and Finishing: Conducting thorough quality checks to ensure the floor meets the required specifications, followed by any necessary finishing work.

Cost and Time Efficiency of Laser Screed Concrete Flooring

Cost-Effective Solution

Laser Screed Concrete Flooring offers a cost-effective solution for large-scale projects. The technology reduces labor costs, minimizes material waste, and shortens project timelines, leading to significant savings over traditional methods.

Quick Turnaround

Thanks to the efficiency of laser screed technology, projects can be completed in a fraction of the time required by traditional methods. This quick turnaround allows clients to move forward with their projects faster, reducing downtime and increasing overall productivity.

Conclusion: Elevate Your Project with Laser Screed Concrete Flooring by Indus Arabia

Laser Screed Concrete Flooring is the ultimate solution for achieving precision, quality, and efficiency in concrete construction. Whether you’re working on an industrial, commercial, or residential project, Indus Arabia has the expertise, equipment, and commitment to deliver exceptional results. Our advanced laser screed technology ensures that your floors will be perfectly level, durable, and built to last.

Ready to elevate your next project with Laser Screed Concrete Flooring? Contact Indus Arabia today to learn more about our services in Saudi Arabia. Visit https://indusarabia.com.sa to request a consultation and discover how we can help you achieve your project goals.

- Schnell Group: Pioneering Innovation in Reinforcement Processing Equipment for Over 30 Years

- Shaping Tomorrow’s Interiors: Gulf Construct Magazine Features FlyBird Hardware’s Visionary CEO, MR. Naveen Singh Parihar

- Innovative Fire and Smoke Curtain Systems: Enhancing Safety Across 30+ Countries

- ACTS: A Global Leader in Engineering, Testing, and Certification Services