In manufacturing, where efficiency and safety are critical to operations, industrial facility management plays an essential role. The complex nature of manufacturing environments means there’s much more to manage than just the physical structure of the building. Machinery, employee safety, compliance with regulations, and maintaining optimal production conditions are all factors that demand attention. Industrial facility management addresses these challenges, offering tailored solutions that enhance both safety and productivity.

Manufacturing facilities often operate with intricate machinery and equipment, which makes them unique compared to other sectors. Managing these systems requires constant monitoring, routine maintenance, and quick response times when issues arise. Without proper facility management, a single malfunction can lead to downtime, lost productivity, or worse—safety hazards that endanger workers. This is why having an expert team in place to manage the facility is critical. It ensures that everything, from electrical systems to ventilation, operates smoothly and safely.

One of the primary challenges in manufacturing is maintaining compliance with safety regulations. Manufacturing environments come with inherent risks, such as working with heavy machinery, hazardous materials, or operating in high-heat conditions. Facility management teams work diligently to ensure these risks are mitigated. Routine inspections, safety audits, and compliance with local and international safety standards help create a secure working environment. This isn’t just about meeting regulations—it’s about protecting workers and reducing the risk of costly accidents or operational interruptions.

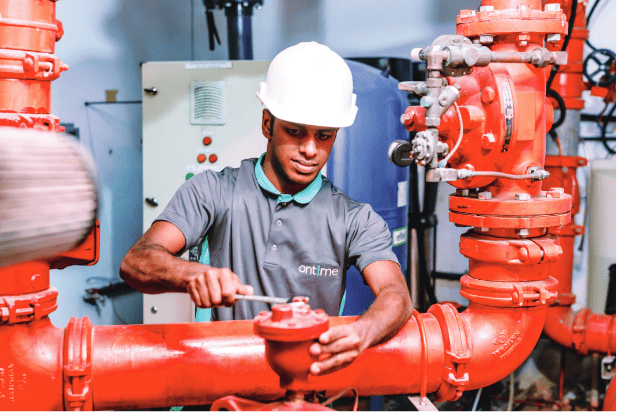

Boosting safety is an integral part of effective facility management in manufacturing. Facility managers are responsible for regular inspections of machinery and equipment, ensuring everything functions as expected. Preventive maintenance is key here—rather than waiting for something to go wrong, facility management teams proactively identify and address potential issues. This approach not only keeps machinery running smoothly but also reduces the chances of safety incidents caused by faulty equipment. For example, malfunctioning machines can lead to accidents or even fires in industrial settings, so routine checks help prevent such outcomes.

Another essential aspect of facility management is implementing and reinforcing safety protocols. This includes everything from signage and personal protective equipment (PPE) requirements to emergency response plans. Employee training is also critical; workers need to know how to handle equipment properly and respond to emergencies effectively. Facility managers ensure that safety training is up-to-date, clear, and tailored to the specific hazards of the manufacturing environment. By doing so, they help minimize the risk of workplace injuries and ensure that everyone knows the protocols in case of an emergency.

While safety is paramount, productivity is the lifeblood of manufacturing operations. Facility management contributes significantly to improving productivity by optimizing the layout of the workspace and streamlining workflows. In manufacturing, time is money. If workers have to navigate poorly designed spaces or face frequent interruptions due to equipment failures, it directly impacts output. Facility management teams analyze and design spaces that promote efficient movement and minimize wasted time. This could include arranging machinery in a more logical order, ensuring materials are easily accessible, or improving lighting to enhance focus and precision in tasks.

Energy management is another area where facility management boosts productivity in manufacturing. Manufacturing facilities consume vast amounts of energy, whether through powering machinery or maintaining optimal environmental conditions for production. Poor energy management can lead to inflated operating costs and reduced profitability. A good facility management team focuses on energy efficiency by monitoring usage, maintaining HVAC systems, and implementing cost-saving initiatives such as LED lighting or energy-efficient machinery. These efforts help reduce energy waste while ensuring that the facility continues to run at full capacity.

One of the major productivity killers in manufacturing is equipment downtime. When machinery breaks down, production grinds to a halt. Facility management teams help prevent this by implementing a preventive maintenance strategy. This involves regular service of machines to address wear and tear before it leads to a breakdown. Predictive maintenance, which uses sensors and technology to monitor equipment performance in real-time, can also be employed. By keeping a close eye on the health of machines, facility managers can identify when something is likely to fail and intervene before it disrupts operations. This significantly reduces downtime and ensures that manufacturing runs smoothly without unexpected halts.

Facility management in manufacturing also involves specialized services that are tailored to the specific needs of industrial environments. For example, HVAC systems in manufacturing plants are often more complex than in other settings due to the need to manage both temperature and ventilation. This is especially important in facilities that deal with hazardous materials or high heat, where proper ventilation can protect both workers and equipment. Facility management ensures that these systems operate efficiently, keeping the air quality high and the working environment safe.

Waste management and sustainability practices are becoming increasingly important in industrial settings. Facility managers play a critical role in ensuring that waste is handled appropriately, whether it’s general waste, hazardous materials, or manufacturing by-products. Sustainable practices such as recycling, energy recovery, and responsible waste disposal are often part of a comprehensive facility management plan. Not only do these initiatives help reduce the environmental impact of manufacturing, but they can also lead to cost savings through more efficient use of resources.

Managing large-scale infrastructure is another critical element of facility management in manufacturing. Industrial facilities are often sprawling, with complex networks of systems that require constant monitoring and maintenance. This could include everything from plumbing and electrical systems to the upkeep of loading docks and warehouses. Facility managers ensure that the infrastructure remains in top condition, focusing on long-term durability and minimizing the risk of costly repairs or replacements down the line.

The benefits of effective facility management in manufacturing are clear. First and foremost, it reduces operational risks, ensuring that employees work in a safe and secure environment. A well-maintained facility also enhances production efficiency, minimizing downtime and maximizing output. Over time, these improvements translate into lower operational costs, as preventive maintenance reduces the need for expensive emergency repairs. Furthermore, an optimized facility leads to better resource management, from energy consumption to waste handling, making operations more sustainable and cost-effective.

In conclusion, industrial facility management is a vital component of manufacturing success. By focusing on safety, productivity, and long-term sustainability, facility management ensures that manufacturing operations run smoothly and efficiently. Whether it’s through regular maintenance, energy management, or optimizing workflows, facility management teams play a critical role in keeping manufacturing facilities at their best. For manufacturers looking to improve their operations, investing in expert facility management is a smart, strategic move that delivers both immediate and long-term benefits.

For more information about Gulfektimal’s services:

- Phone: +966 56 039 2669

- Website: www.gulfektimal.com

- Email: info@gulfektimal.com